Infrastructure

- Home

- Infrastructure

Infrastructure

Our vertically integrated facility allows us to produce an eclectic range of textile products with remarkable quality at short-lead times. We offer innovative and top-of-the-line woven solutions with functional finishes and a wide range of prints.

BKS Textiles is a vertically integrated facility from yarn dyeing and weaving to finishing, with a modern production facility located in Southern India housing hi-tech machinery and equipment. We source superior-quality yarns to produce the finest woven apparel fabrics, workwear and home textiles to meet the distinct needs of our clients worldwide.

We manufacture products with woven fabrics produced in our mills and deliver them to several high-end retailers and brands worldwide. We are meticulous about the products we manufacture and ensure safe working conditions while adhering to rigid quality control measures and ethical practices. At BKS Textiles, we embrace eco-friendly and sustainable practices to guarantee the well-being of our people and environment.

Weaving Preparatory

Our weaving preparatory unit forms the core of our operations, equipped with the latest hi-tech machinery that gives life to our fabrics. Our modern facility houses four automatic warping machines and two multi-cylinder sizing machines that enable us to feed warp to in-house weaving as well as for vendor operations.

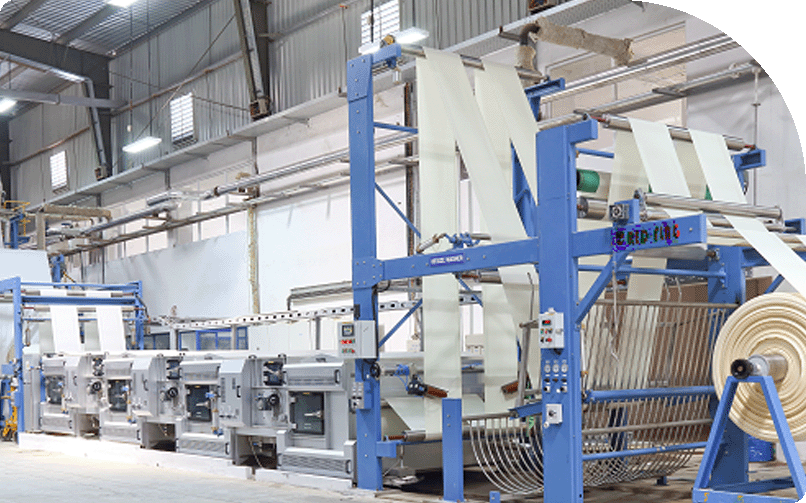

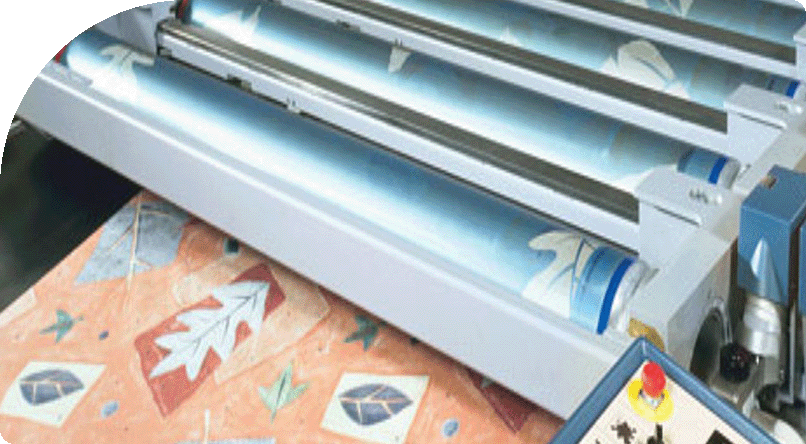

Processing

The BKS processing facility located in SIPCOT Perundurai Erode houses cutting-edge machinery, including a Continuous Bleaching Range (CBR), Continuous Dyeing Range (CDR), and Rotary printing machines, to ensure your fabrics are finished to perfection. We can expertly handle greige fabrics up to 78 & and finish up to 72 & and offer a range of processing possibilities on 100% cotton, polycotton, 100% polyester, viscose, poly-viscose, linen, tencel, modal, and blended fabrics.

Read More

Coating

Our latest addition to our manufacturing process allows us to produce the best coated technical textiles, with the perfect blend of style and functionality. Our coating division is equipped with advanced machinery that can handle woven fabrics up to 70 & (178 cm) wide and has a production capacity of an impressive 20,000 metres per day.

Read More